Field termination plugs (such as MPTL link specific jumper plugs) can support high-speed network cabling, but must meet specific design and process requirements. The following are the key points:

1. High frequency performance support capability

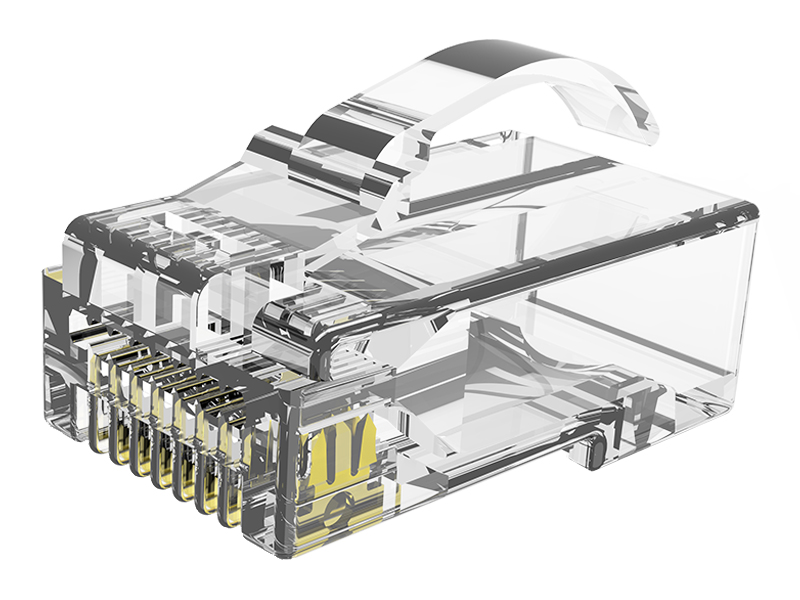

Specialized structural design: High performance jumper plug with built-in PCB compensation circuit, which can suppress signal crosstalk and improve bandwidth margin (such as Cat.6A supporting 500MHz, meeting 10Gbps transmission).

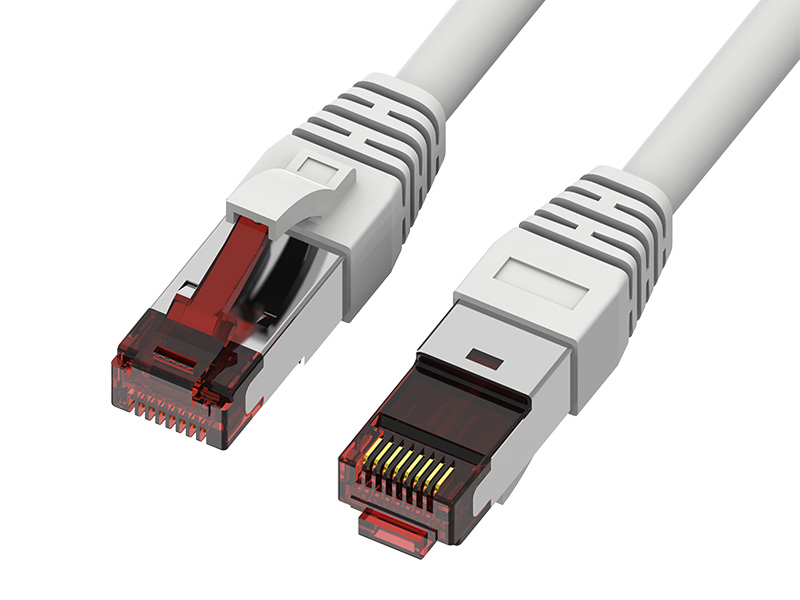

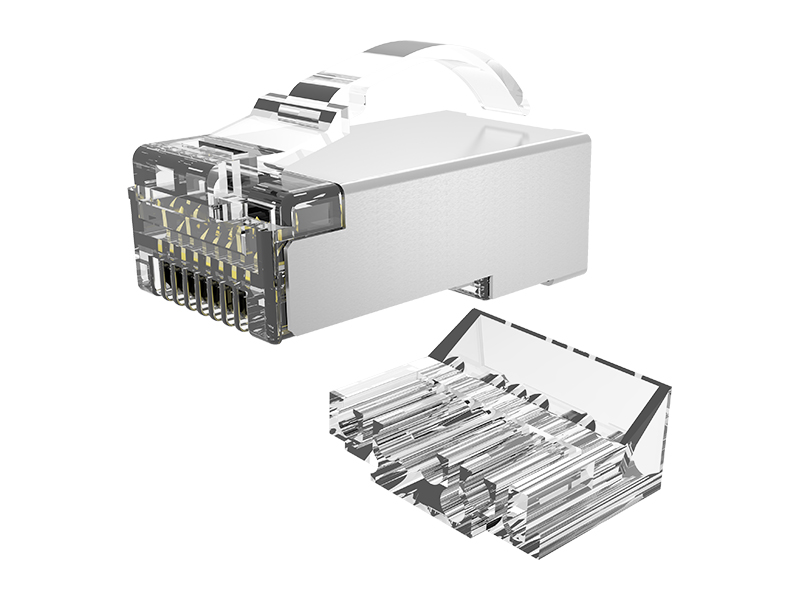

Shielding optimization: The fully shielded plug (360 ° metal wrapping) combined with shielded cables can resist external electromagnetic interference and ensure the stability of gigabit/ten gigabit data transmission.

2. Reliability impact of installation process

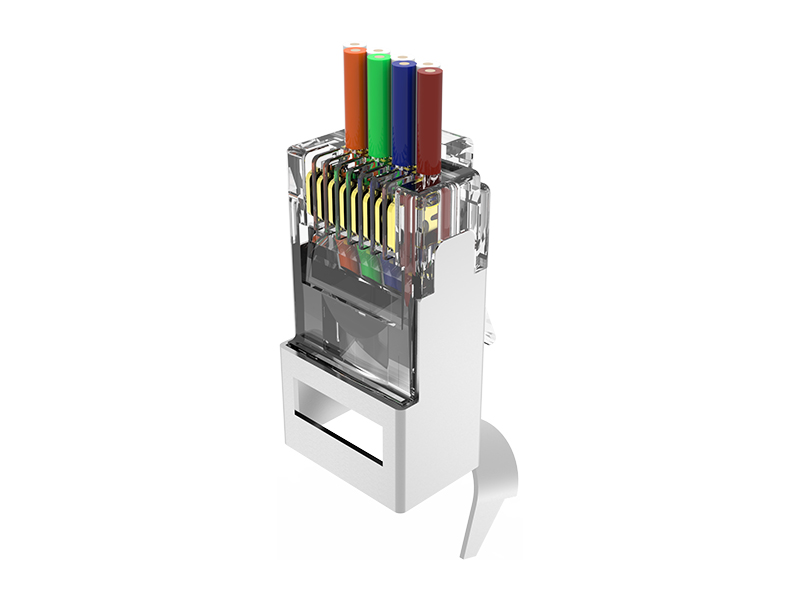

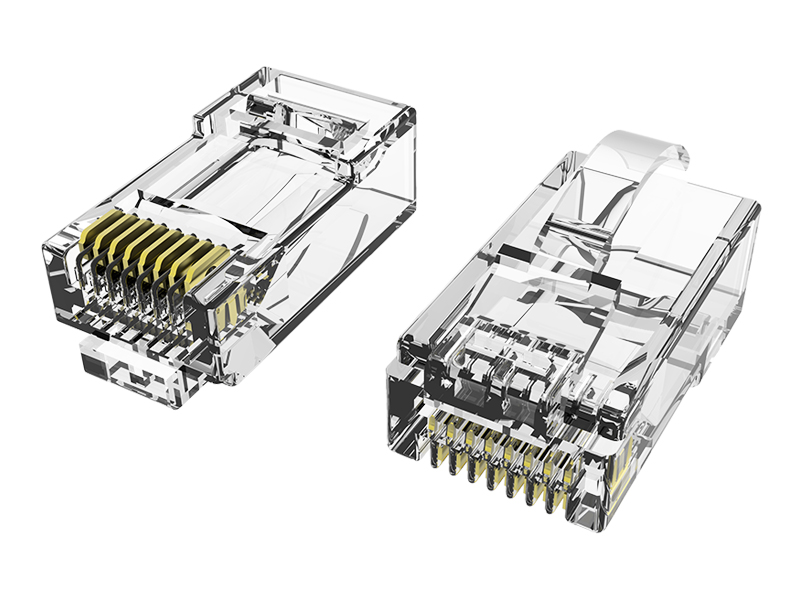

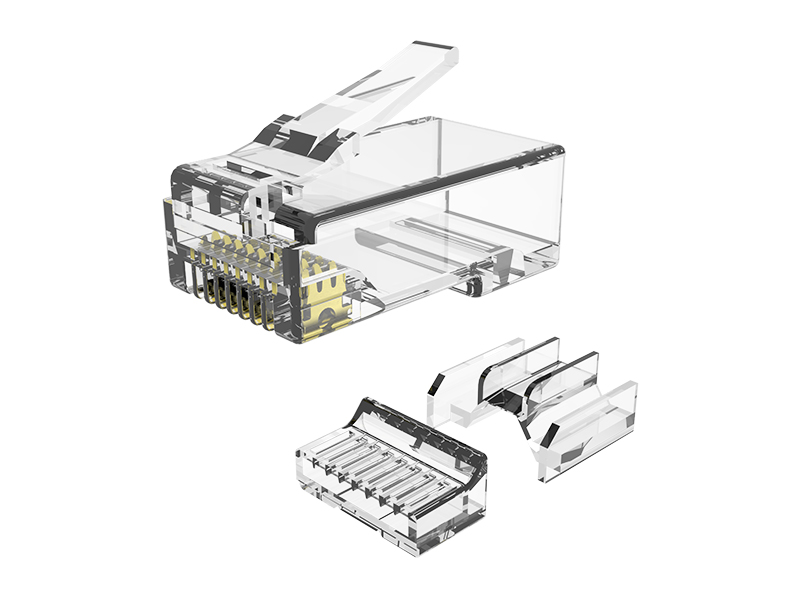

Differences in termination methods: Traditional crystal head crimping can easily damage thick wire diameter network cables (such as 23AWG), leading to performance degradation; The jump plug adopts IDC wire terminals, similar to module termination, for more reliable contact.

Improved fault tolerance: Jumping plugs support re termination (accidental operation can remove the core and press it down), avoiding the problem of single scrap of crystal heads and reducing construction losses.

3. Adaptability to application scenarios

Advantages of fixed terminal direct connection: Suitable for fixed installation scenarios such as PoE cameras, wireless APs, industrial equipment, etc., eliminating the need for panels and jumpers, reducing failure points, and improving security.

Attention to space limitations: Some plugs have a large volume (such as PCB models), and it is necessary to confirm the compatibility of the device interface space in advance.

4. Strengthening the demand for industrial environment

Protection and weather resistance: Industrial grade plugs must have IP67 protection, high and low temperature resistance (-40 ℃~75 ℃), and anti vibration characteristics to ensure long-term stability in harsh environments.

PoE power supply compatibility: Special gold-plated contact design (such as crown shaped pins) can reduce arc corrosion and support 90W PoE++power supply without damaging the interface.

5. Standards and Testing Certification

Compliance requirements: The MPTL link model must comply with the TIA-568.2-D standard definition and undergo certification testing using a dedicated adapter (such as Fluke DSX jumper adapter).

The importance of factory pre inspection: Brand jump plugs undergo full performance testing (such as crosstalk and return loss) before leaving the factory, which is easier to pass channel acceptance than on-site crimping of crystal heads.

| Factor | Critical Requirements | Key Limitations | Implementation Guidance |

| High-Frequency Performance | Must integrate signal-compensating PCBs to suppress crosstalk & meet bandwidth targets (e.g., Cat.6A/500MHz for 10Gbps). | Non-compensated plugs cause signal distortion & fail certification. | Use engineered plugs (e.g., MPTL-rated) with verified high-frequency PCBs. |

| Shielding Integrity | Requires 360° full-metal shielding + shielded cables to block EMI/RFI. Essential for PoE stability & multi-gigabit speeds. | Partial/unshielded plugs introduce noise, packet loss & speed drops. | Pair FTP/STP plugs with shielded cabling. Ground shield properly. |

| Termination Reliability | IDC punch-down terminals (not RJ45 crimp) prevent wire deformation & enable re-termination if miswired. | Crimp-style RJ45 plugs damage thick conductors (e.g., 23AWG), degrading performance. | Avoid crimping; use IDC tool-terminated plugs only. Verify wire seating depth. |

| Standards Compliance | Must align with TIA-568.2-D MPTL (Modular Plug Terminated Link) topology for direct device connections. | Non-MPTL designs violate channel models, risking test failures. | Select TIA-certified plugs & test with MPTL-adapted certifiers (e.g., Fluke DSX). |

| Environmental Durability | Industrial use demands IP67 sealing, vibration resistance, and wide-temperature contacts (-40°C to 75°C) for harsh settings. | Consumer-grade plugs fail in moisture/dust/vibration, causing disconnects. | Deploy industrial-hardened plugs with corrosion-resistant plating (e.g., gold over nickel). |

| PoE Compatibility | Contacts must handle high-current PoE++ (90W) without arcing/overheating via optimized contact geometry (e.g., crown springs). | Thin/unguided pins overheat under PoE loads, leading to melted connectors. | Prioritize plugs with PoE-optimized contact arrays & thermal safety margins. |

| Space Constraints | Compact plug designs essential for tight spaces (e.g., cameras, APs). | Bulky PCB-enhanced plugs may obstruct adjacent ports or strain device jacks. | Verify physical clearance before deployment. Avoid PCB plugs where space is critical. |

中文简体

中文简体 English

English Français

Français Deutsch

Deutsch عربى

عربى