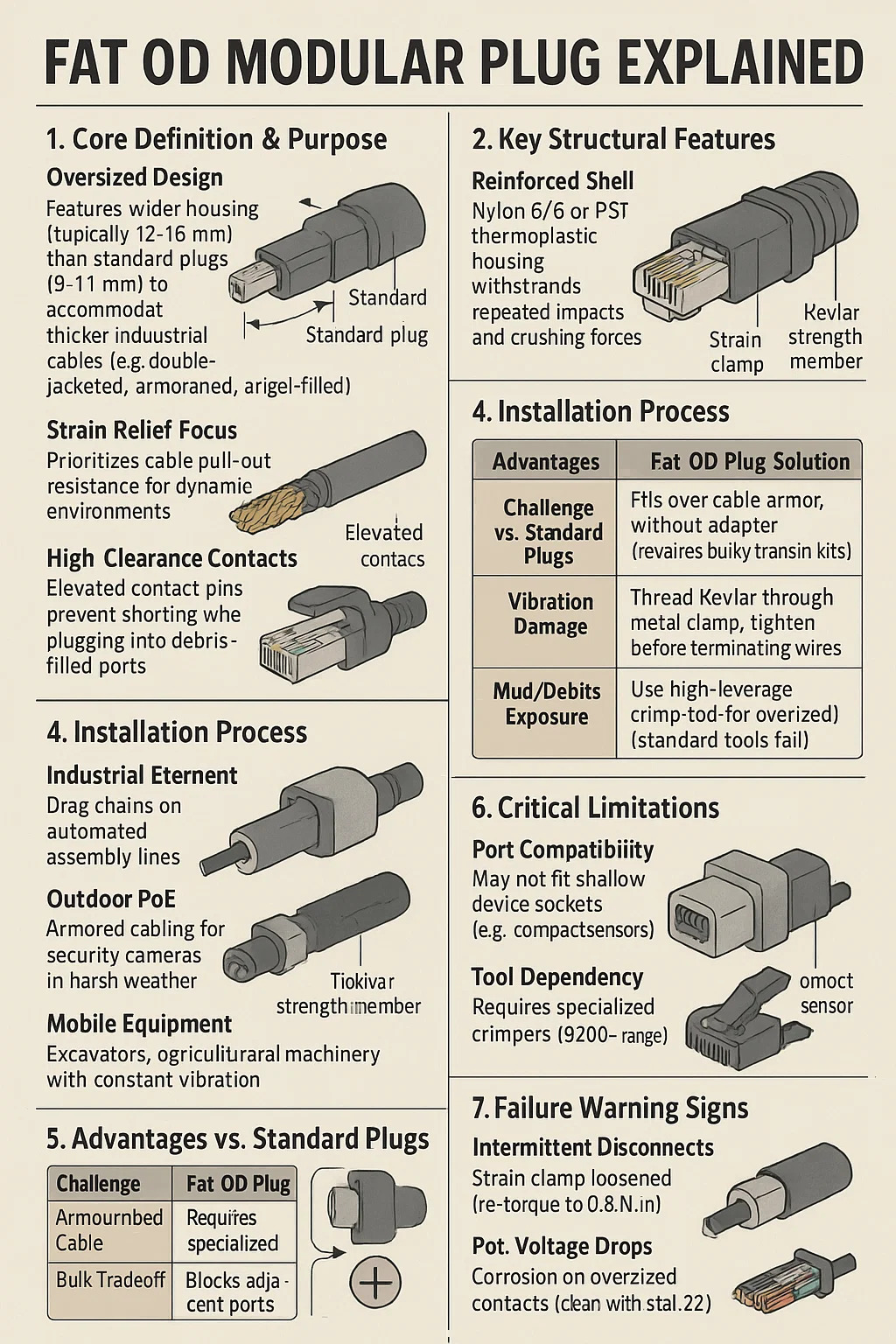

Fat OD Modular Plug Explained

1. Core Definition & Purpose

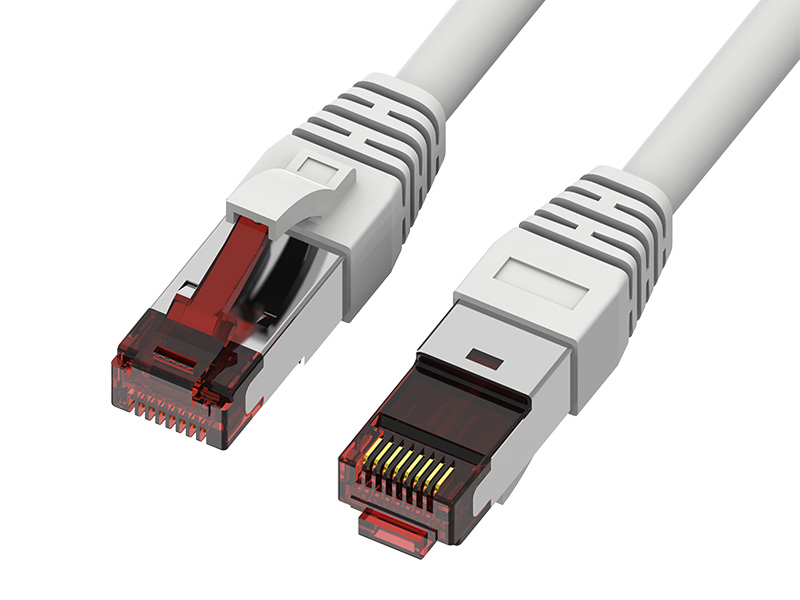

Oversized Design: Features a wider housing (typically 12–16mm diameter) than standard plugs (9–11mm) to accommodate thicker industrial cables (e.g., double-jacketed, armored, or gel-filled).

Strain Relief Focus: Prioritizes cable pull-out resistance for dynamic environments (robotics, conveyors, heavy machinery).

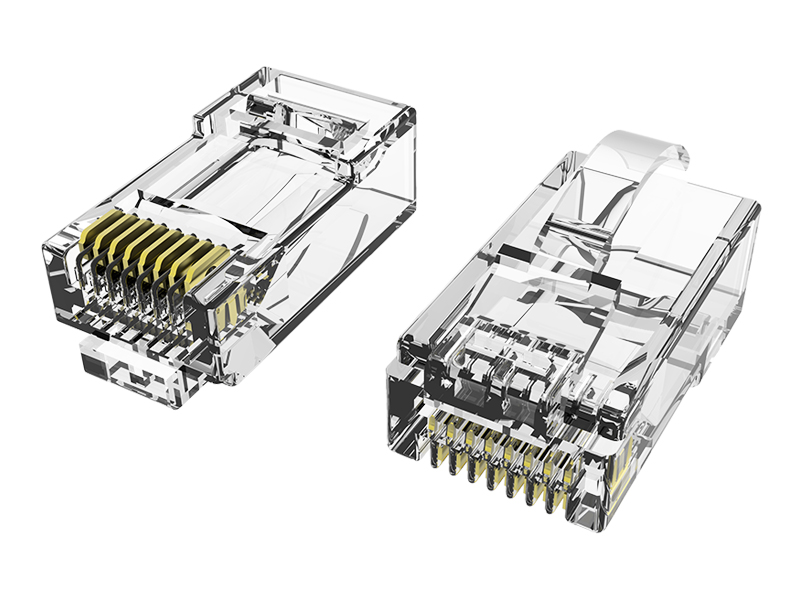

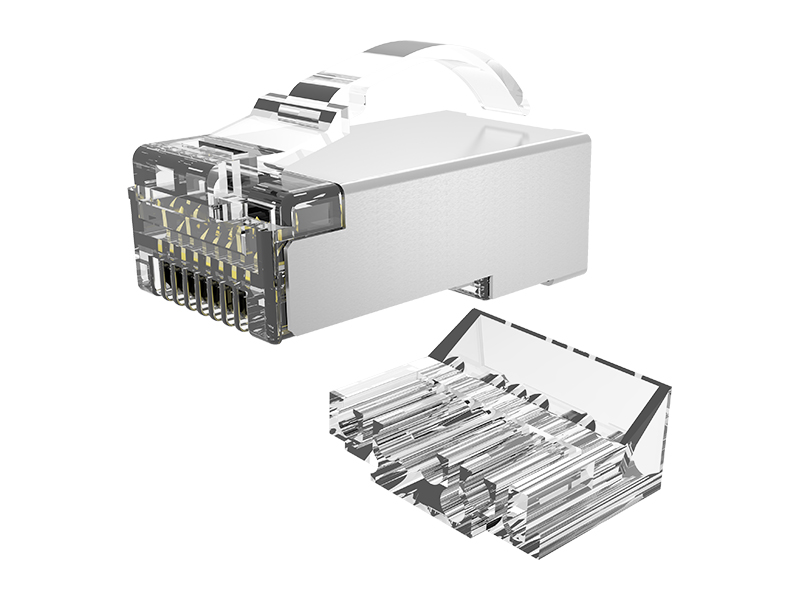

2. Key Structural Features

Reinforced Shell:

Nylon 6/6 or PBT thermoplastic housing withstands repeated impacts and crushing forces.

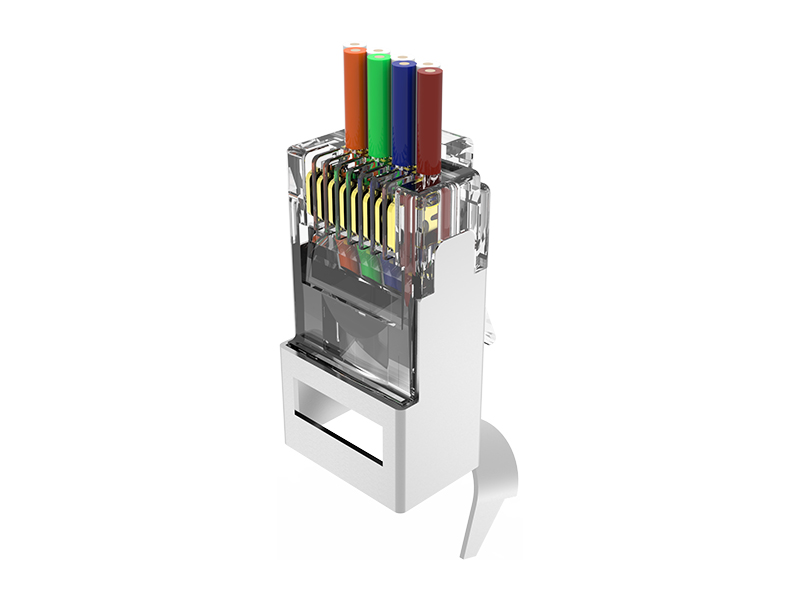

Dual-Point Strain Clamp:

Metal teeth grip cable jacket + Kevlar strength member separately.

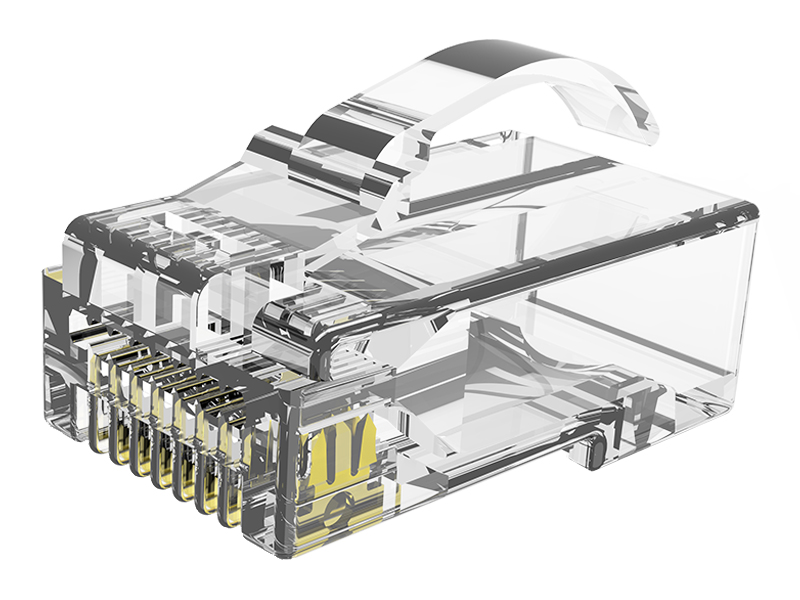

High-Clearance Contacts:

Elevated contact pins prevent shorting when plugging into debris-filled ports.

3. Typical Applications

Industrial Ethernet:

Drag chains on automated assembly lines.

Outdoor PoE:

Armored cabling for security cameras in harsh weather.

Mobile Equipment:

Excavators, agricultural machinery with constant vibration.

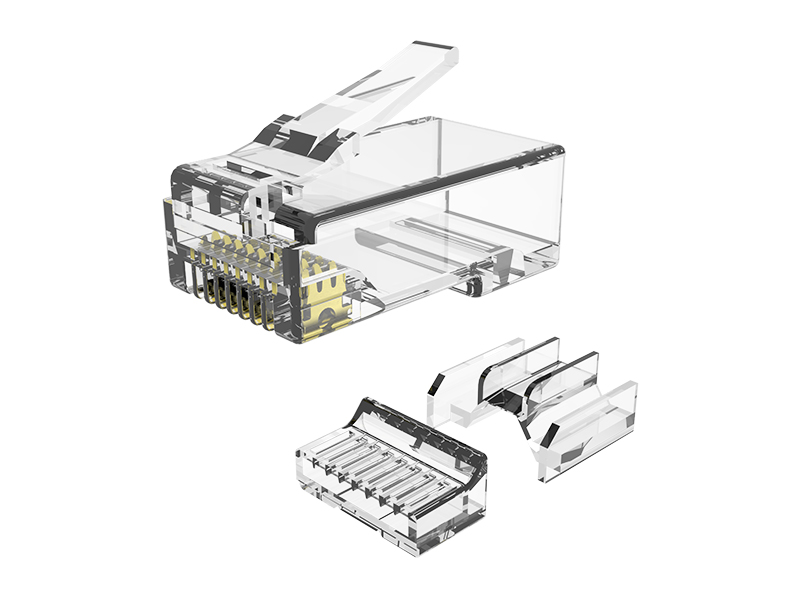

4. Installation Process

Cable Prep:

Strip outer jacket to expose 40–50mm length (reveals strength member + conductors).

Strength Member Lock:

Thread Kevlar through metal clamp; tighten before terminating wires.

Termination:

Use high-leverage crimp tool for oversized contacts (standard tools fail).

5. Advantages vs. Standard Plugs

| Challenge | Fat OD Plug Solution | Standard Plug Risk |

|---|---|---|

| Armored Cable Routing | Fits over cable armor without adapter | Requires bulky transition kits |

| Vibration Damage | Dual clamping prevents conductor fatigue | Wires snap at contact points |

| Mud/Debris Exposure | Elevated contacts avoid ground shorts | Debris bridges contacts |

6. Critical Limitations

Port Compatibility:

May not fit shallow device sockets (e.g., compact sensors).

Tool Dependency:

Requires specialized crimpers ($200+ range).

Bulk Tradeoff:

Occupies 2–3× more space than RJ45; blocks adjacent ports.

7. Failure Warning Signs

Intermittent Disconnects: Strain clamp loosened (re-torque to 0.8 N·m).

PoE Voltage Drops: Corrosion on oversized contacts (clean with stabilant 22).

Cable Jacket Slippage: Kevlar not secured in metal teeth.

中文简体

中文简体 English

English Français

Français Deutsch

Deutsch عربى

عربى