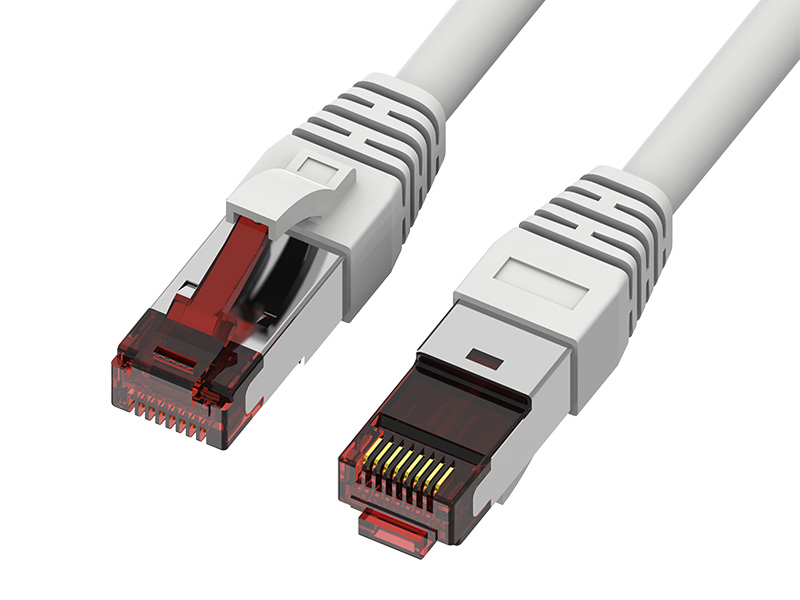

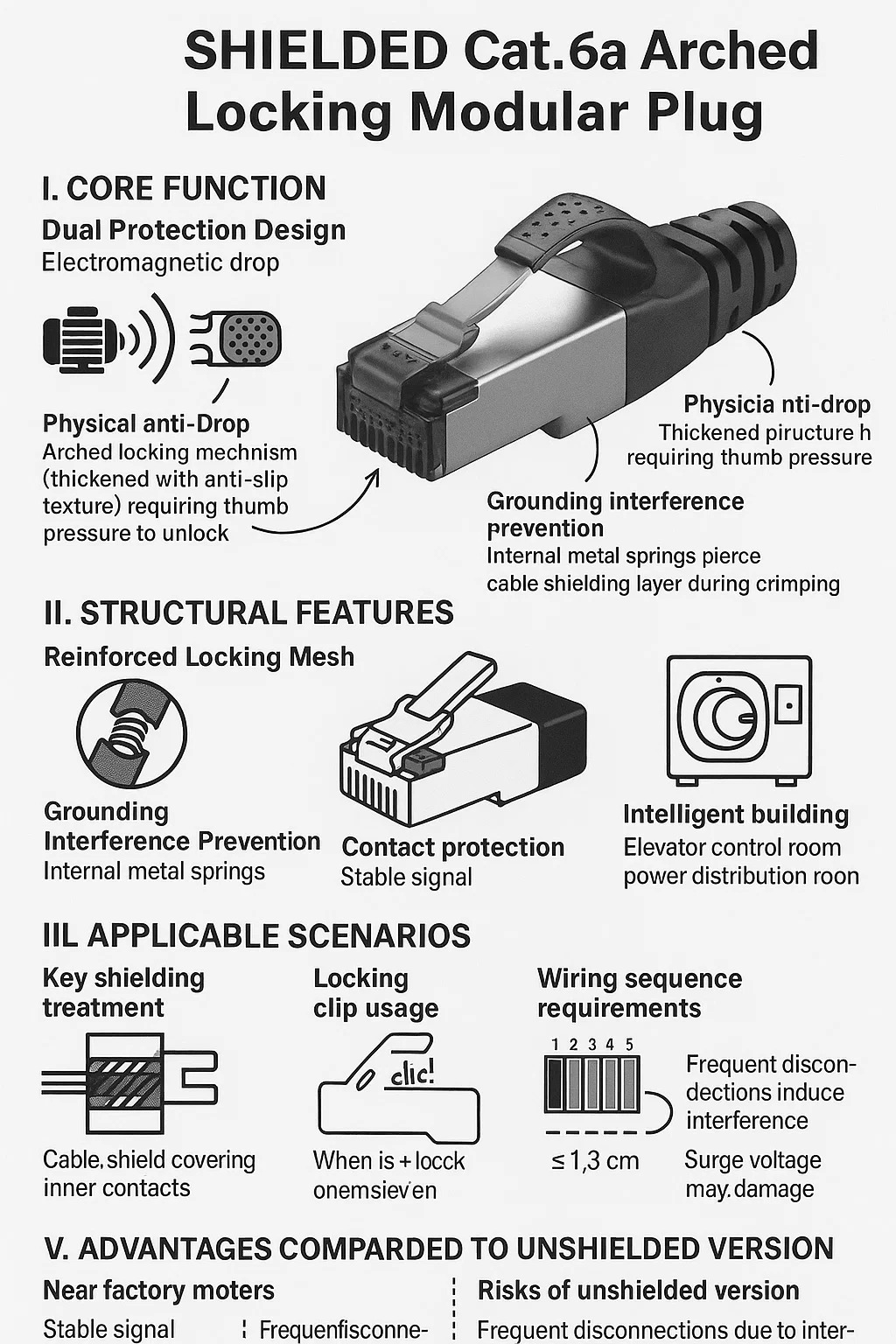

Detailed Explanation of Shielded Cat.6a Arched Locking Modular Plug

Content

I. Core Function

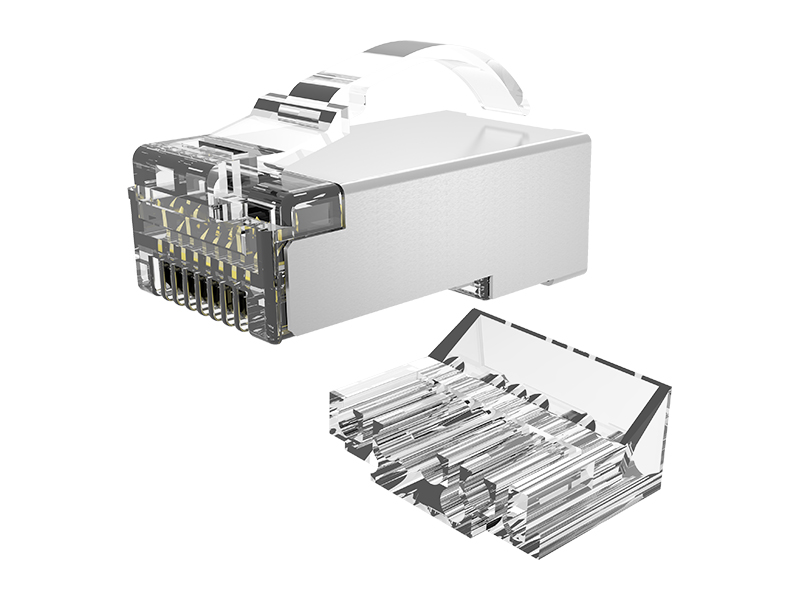

Dual Protection Design:

Electromagnetic Interference Resistance: The metal shell (zinc alloy or nickel plating) encases the plug, acting like a "radiation shield" to block signal interference from motors, inverters, and other equipment.

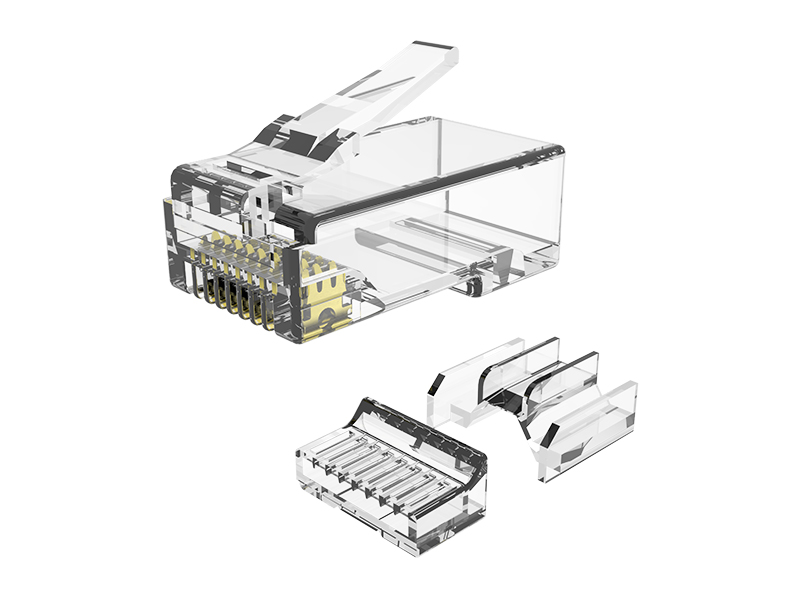

Physical Anti-Drop: The arched locking mechanism (thickened with anti-slip texture) requires thumb pressure to unlock, preventing breakage when the cable is kicked, hooked, or accidentally pulled.

II. Structural Features

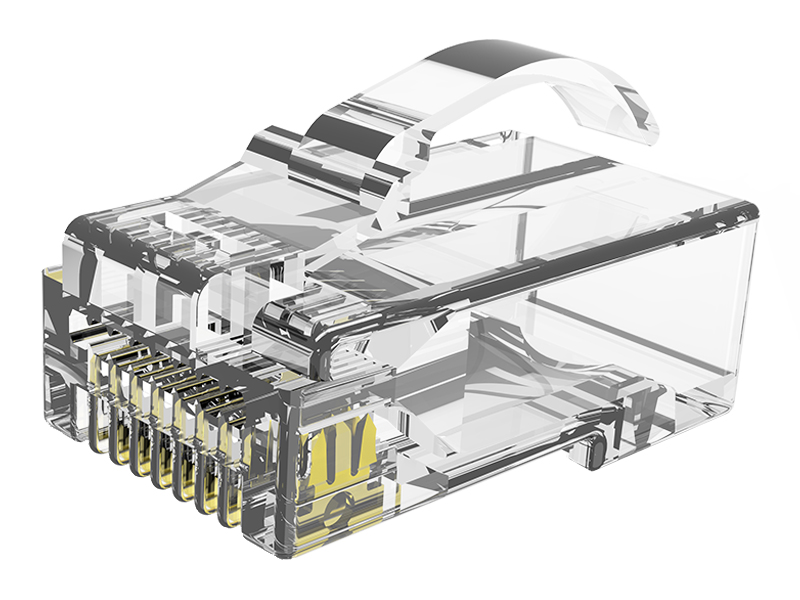

Reinforced Locking Mesh: The arched section is thicker than ordinary plugs, making it less prone to breakage from being run over or stepped on.

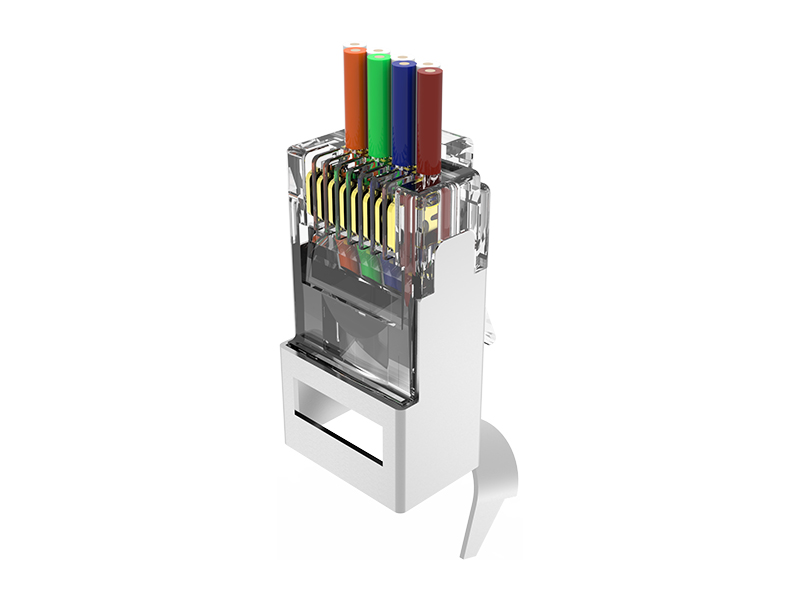

Grounding Interference Prevention: The plug contains internal metal springs that automatically pierce the cable shielding layer during crimping, diverting interference to the equipment's ground (e.g., switch housing).

Contact Protection: Gold-plated contacts are rust- and oxidation-resistant, remaining functional even after repeated insertion and removal.

III. Applicable Scenarios

Industrial Workshops: Near CNC machine tools and motors—the shielding layer blocks electrical spark interference, and the locking mechanism resists equipment vibration.

Medical Imaging Room: Near MRI and CT equipment – Avoid electromagnetic interference affecting medical data transmission.

Intelligent Building: Elevator control room, power distribution room – Resistant to strong electrical interference; locking clips prevent accidental wire breakage during maintenance.

IV. Installation Precautions

Key Shielding Treatment: The cable's metal shielding mesh must completely cover the internal metal contacts of the plug; otherwise, interference protection will fail.

Locking Clip Usage Tips: A "click" sound when inserting the device indicates it is locked; when unplugging the cable, press the locking clip at an angle (do not pull the cable forcefully).

Wiring Sequence Requirements: Wiring should follow the T568B sequence; wire pairs should be untwisted to ≤1.3 cm (excessive length will reduce speed).

V. Common Problem Avoidance

| Mistake | Consequence | Proper Method |

|---|---|---|

| Shield layer not contacting metal shell | Shielding fails → speed crashes | Visually verify full coverage before crimping |

| Prying latch vertically | Latch snaps | Press at 45° angle to release |

| Using unshielded cable | Zero EMI protection | Pair only with shielded cabling |

VI. Advantages Compared to Unshielded Version

| Scenario | Shielded Cat.6a Arch Latch Plug | Unshielded Plug Risks |

|---|---|---|

| Near factory motors | Zero packet loss – Blocks EMI noise | Frequent disconnects – EMI corrupts signals |

| Sensitive equipment rooms | Prevents static damage – Grounds ESD | Power surges fry ports – No discharge path |

中文简体

中文简体 English

English Français

Français Deutsch

Deutsch عربى

عربى