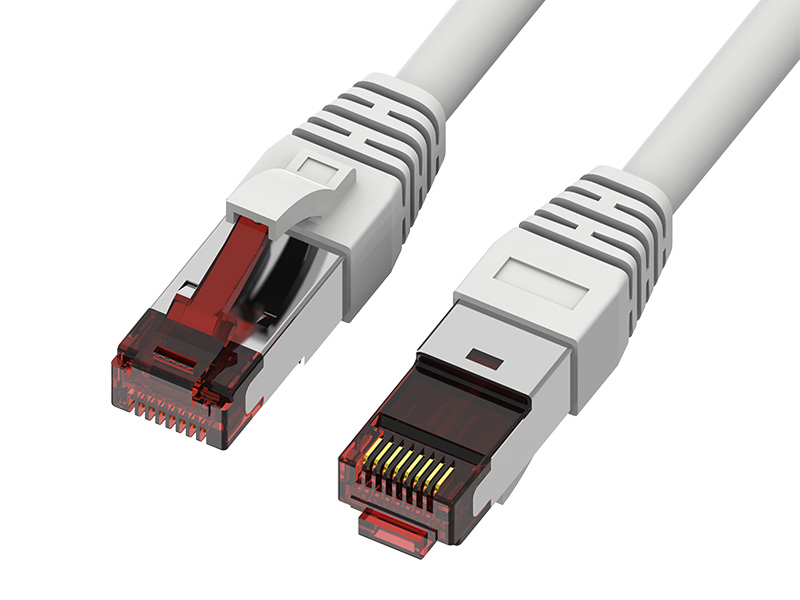

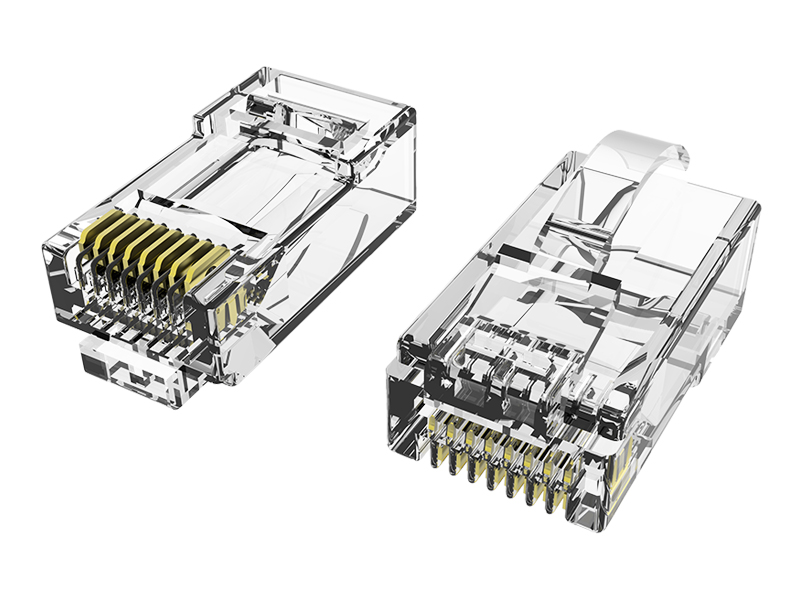

Unshielded Cat.5e Arch Latch Modular Plug

Content

1. Core Design Purpose

Secure Physical Retention: Features an arched latch (raised, ribbed tab) for high-tension grip, preventing accidental unplugging in vibration-prone areas (e.g., under desks, workshop floors).

Basic Performance: Supports 1Gbps Ethernet for office/light industrial use where EMI is minimal.

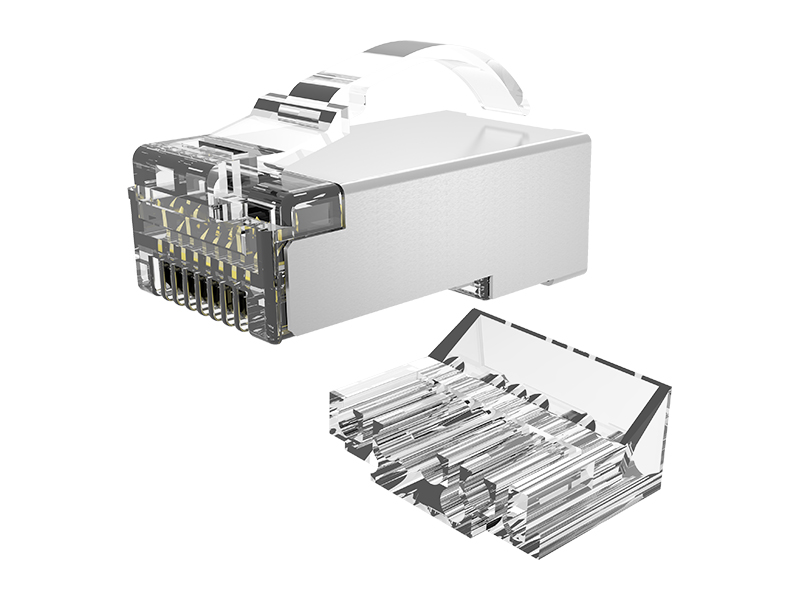

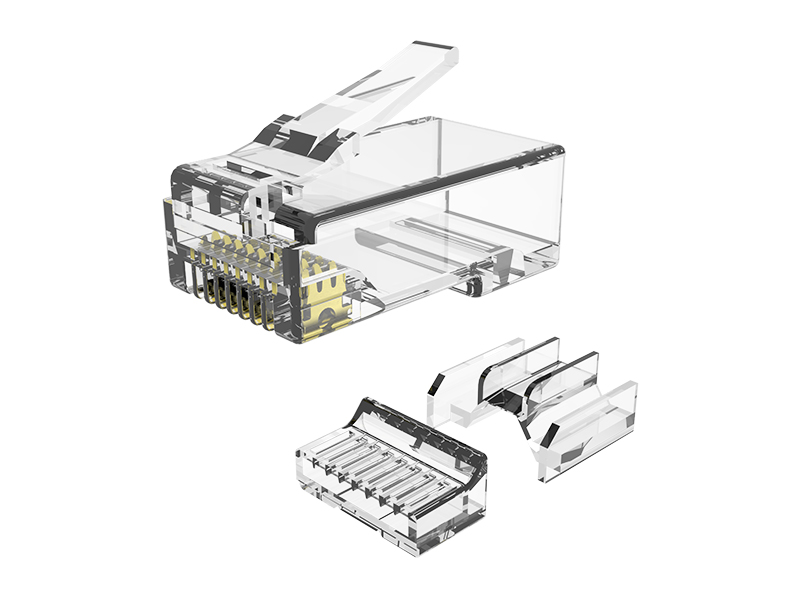

2. Key Physical Features

Reinforced Latch:

Thickened arch design resists snapping when snagged by feet, carts, or equipment.

Strain Relief:

Internal ramps grip cable jacket (no Kevlar needed), surviving 50+ lbs pull force.

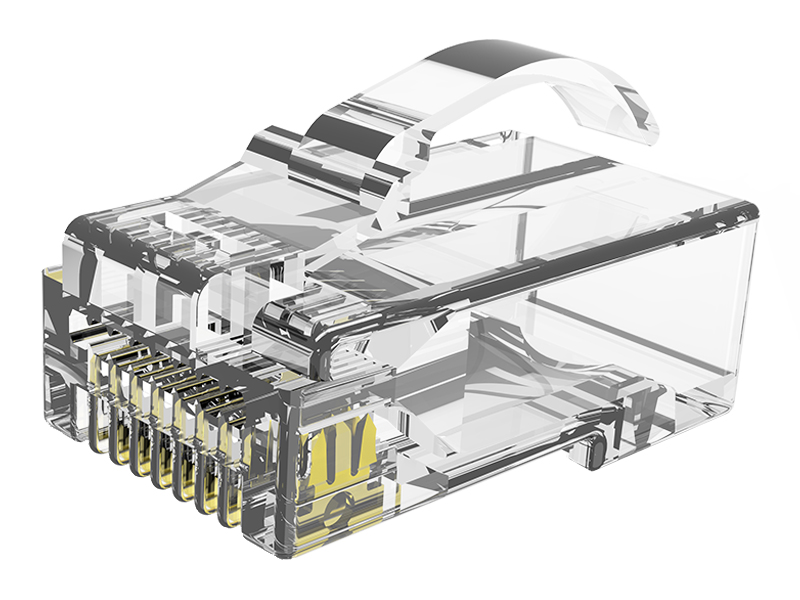

Tool-Less Simplicity:

No clips or screws—latch releases by thumb press at 45° angle.

3. Termination Process

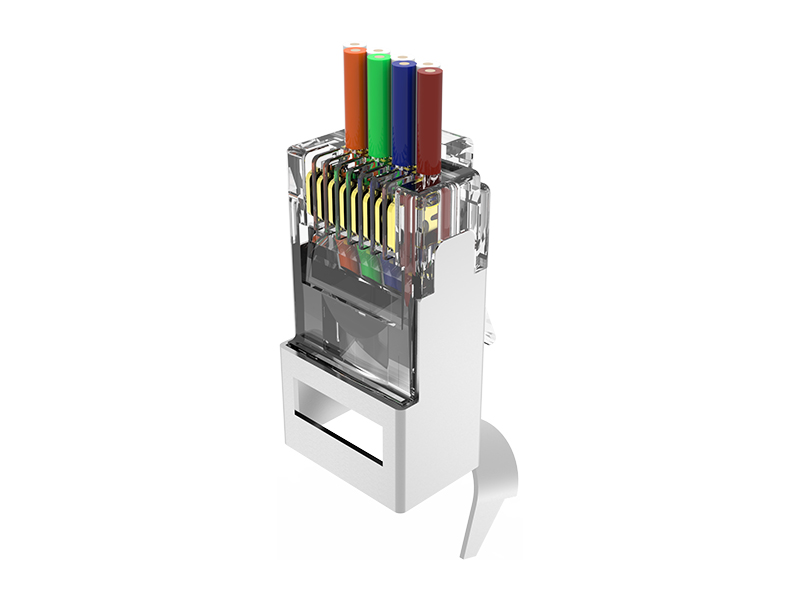

Strip & Align:

Remove ½" jacket; arrange wires in T568B order (no untwisting >13mm).

Slide & Seat:

Push wires into plug until tips hit front wall.

Crimp:

Squeeze with standard crimper; latch auto-deploys post-compression.

4. Target Applications

Retail POS Systems:

Secures cables kicked by customers under counters.

Education Labs:

Withstands chair legs rolling over cords.

Light Industrial:

Conveyor side stations with low vibration.

5. Failure Scenarios & Fixes

| Issue | Cause | Survival Fix |

|---|---|---|

| Latch Snaps | Vertical yank (not angled press) | Pry release with flathead screwdriver |

| Intermittent Signal | Wires retracted during crimping | Slice plug; re-terminate |

| Plug Ejection | Latch worn smooth from debris | Wrap electrical tape as temp lock |

6. Limitations

No Shielding: Fails near motors, microwaves, or high-voltage lines.

Cat.5e Only: Not for 10Gbps upgrades.

Reusability: Latch weakens after 5+ removals; replace if loose.

7. Vs. Standard Cat.5e Plug

| Scenario | Arch Latch Plug | Standard Plug |

|---|---|---|

| Kick/Pull Test | Holds at 50N force | Pops out at 20N |

| Blind Installation | Latch clicks audibly when seated | No feedback |

| Cable Tension | Redirects stress to housing | Stresses wire contacts |

中文简体

中文简体 English

English Français

Français Deutsch

Deutsch عربى

عربى