1. Tools & Materials Required

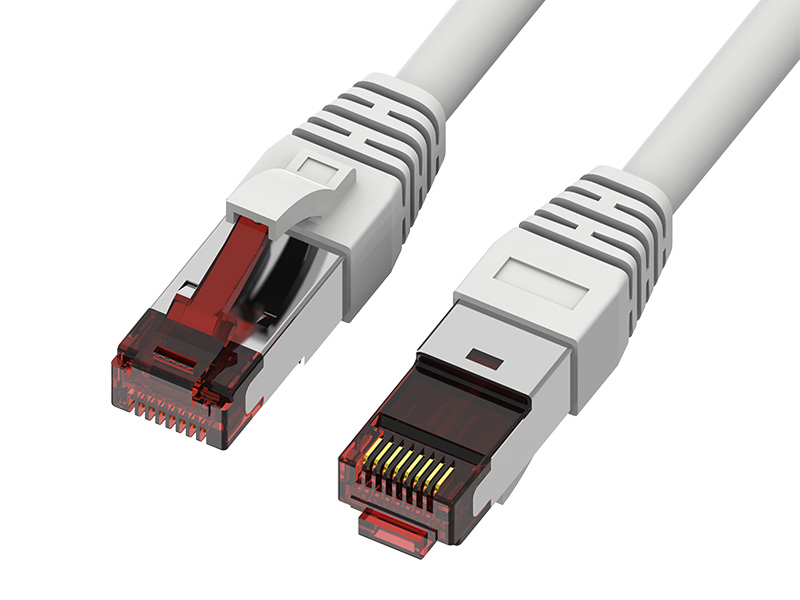

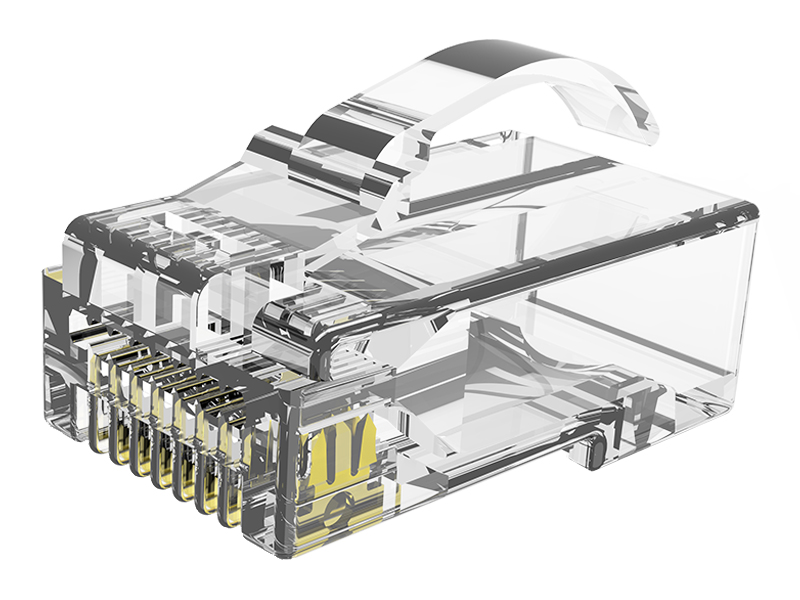

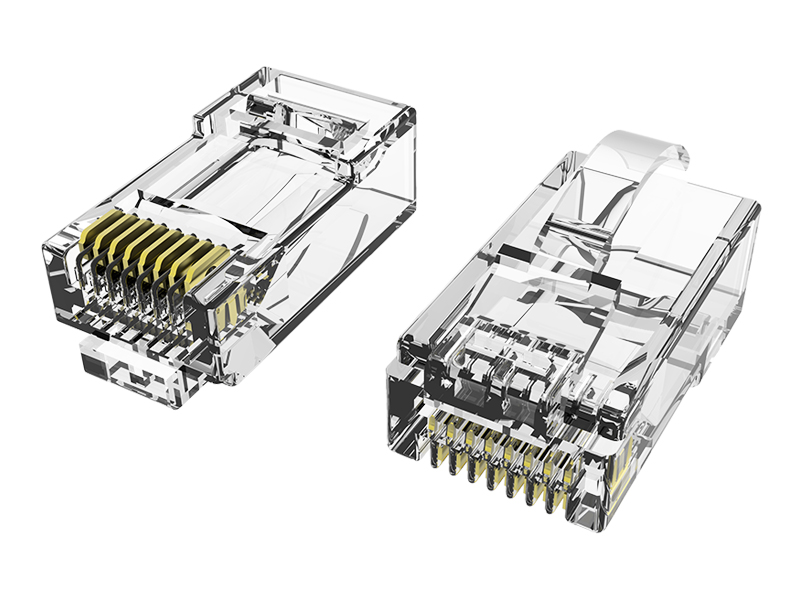

Field termination plug (RJ45, M12, or other type).

Cable stripper (for precise jacket removal).

Punch-down tool (for IDC termination).

Cable tester (to verify continuity & performance).

Scissors or flush cutters (for trimming wires).

2. Step-by-Step Installation

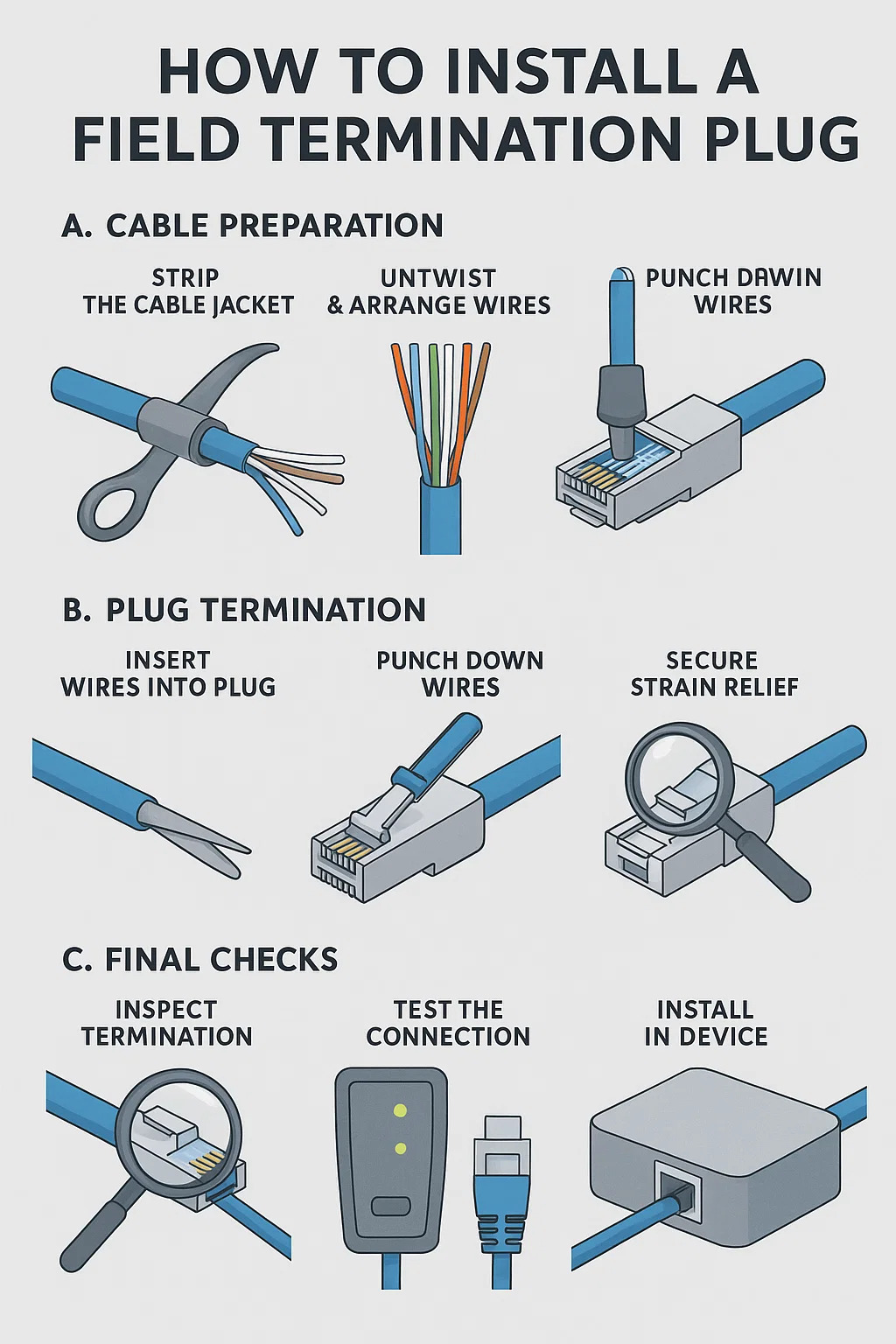

A. Cable Preparation

--Strip the Cable Jacket

Use a stripper to remove 1-1.5 inches of the outer jacket.

Avoid nicking inner conductors.

--Untwist & Arrange Wires

Follow the plug's color code (T568A or T568B).

Keep twists intact up to the termination point.

--Trim Wires to Length

Cut wires evenly, leaving 0.25-0.5 inches exposed.

B. Plug Termination

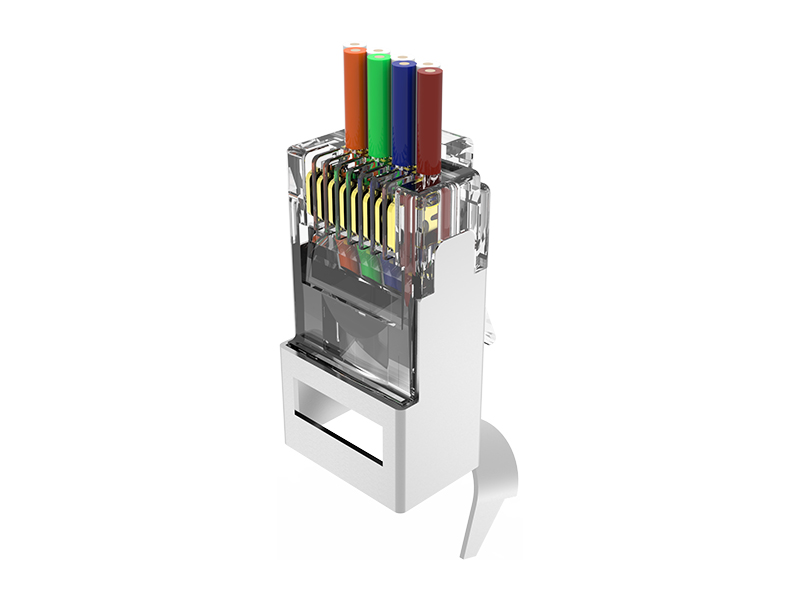

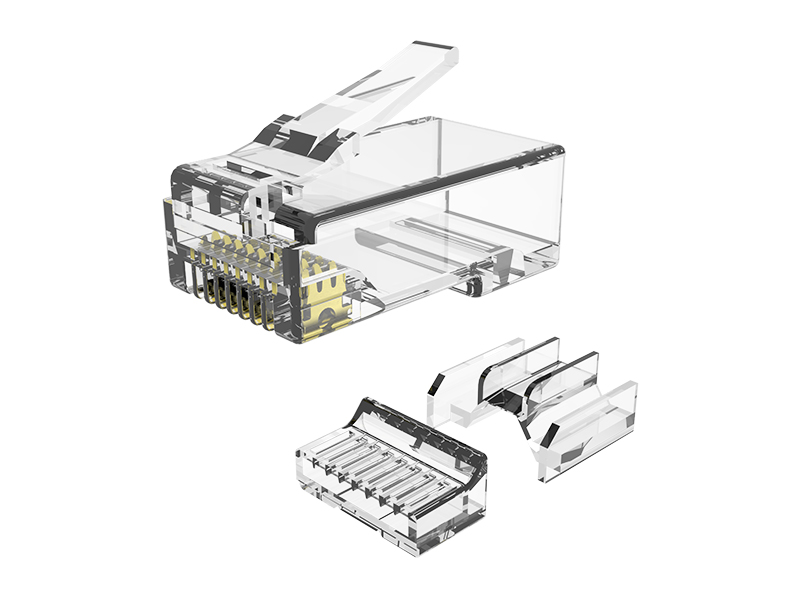

--Insert Wires into Plug

Align conductors with the plug's IDC slots.

Ensure no crossed or loose wires.

--Punch Down Wires

Use a punch-down tool to seat wires firmly.

Apply even pressure to avoid partial connections.

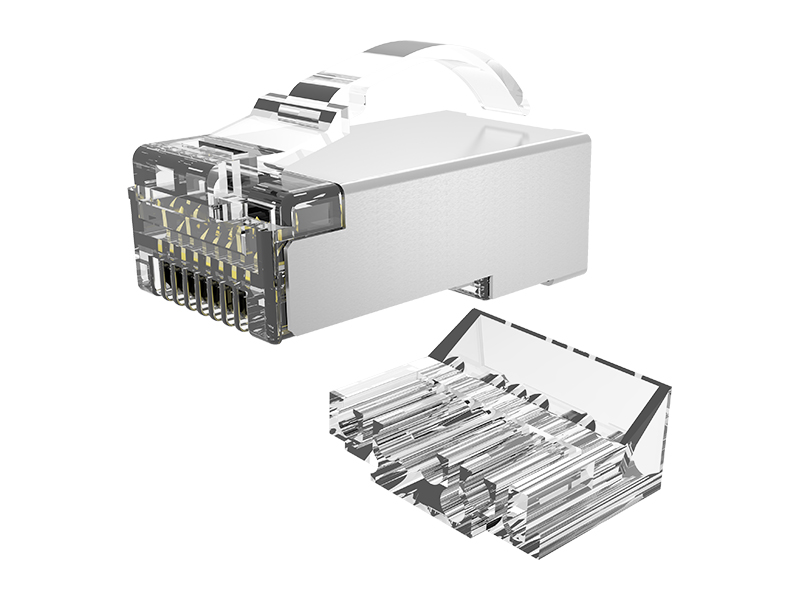

--Secure Strain Relief

Clamp the cable jacket inside the plug to prevent pullout.

C. Final Checks

--Inspect Termination

Verify no stray wire strands or misaligned contacts.

--Test the Connection

Use a cable certifier (for high-speed networks) or continuity tester.

--Install in Device

Plug into the target device (IP camera, AP, etc.) and confirm functionality.

3. Common Mistakes to Avoid

Over-trimming wires → Poor contact.

Incorrect wire order → Signal failure.

Skipping strain relief → Cable damage over time.

Not testing after install → Hidden faults.

4. When to Re-Terminate

If testing fails (open/short circuits).

If the plug feels loose or unstable.

If corrosion or damage is visible.

| Step | Action | Critical Details | Tool/Check |

| 1. Strip Cable | Remove 1–1.5 inches of outer jacket without damaging inner conductors. | Avoid cutting into wire insulation; preserve twists near jacket end. | Cable stripper + visual inspection. |

| 2. Arrange Wires | Untwist and align wires to T568A/B scheme. | Maintain twists up to IDC slots; no crossed pairs. | Follow plug’s color guide (printed or molded). |

| 3. Trim Wires | Cut wires to 0.25–0.5 inches exposed. | Ensure uniform length; no frayed ends. | Flush cutters (scissors risk uneven cuts). |

| 4. Insert into Plug | Seat wires into plug’s IDC slots until fully seated. | Wires must reach terminal bottoms; no gaps or misalignment. | Magnifying glass (verify seating under poor lighting). |

| 5. Punch Down | Terminate wires with punch-down tool at 45° angle. | Single firm press per wire; avoid partial punches or over-compression. | Impact punch-down tool (non-impact may require multiple strikes). |

| 6. Secure Strain Relief | Clamp cable jacket inside plug body. | Jacket must be gripped tightly; no exposed wires outside plug. | Tug test: gentle pull to confirm strain relief holds. |

| 7. Test Connection | Verify continuity, wire map, and (if applicable) PoE/signal stability. | Check for opens/shorts; validate impedance for high-speed links. | Cable certifier (e.g., Fluke) or basic tester for pass/fail. |

| 8. Install in Device | Connect to endpoint (camera, AP, etc.) and confirm operation. | Ensure plug locks securely; no intermittent disconnects. | Functional test (e.g., ping, video feed, PoE power check). |

中文简体

中文简体 English

English Français

Français Deutsch

Deutsch عربى

عربى