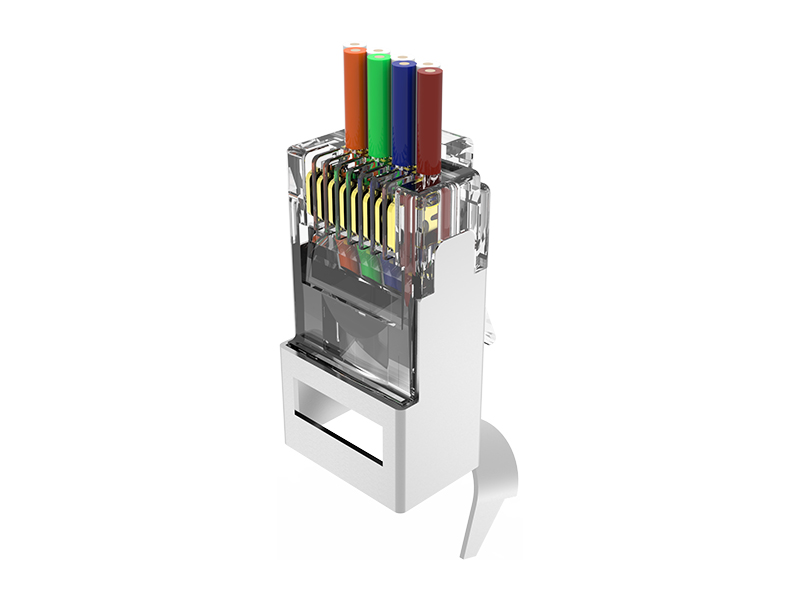

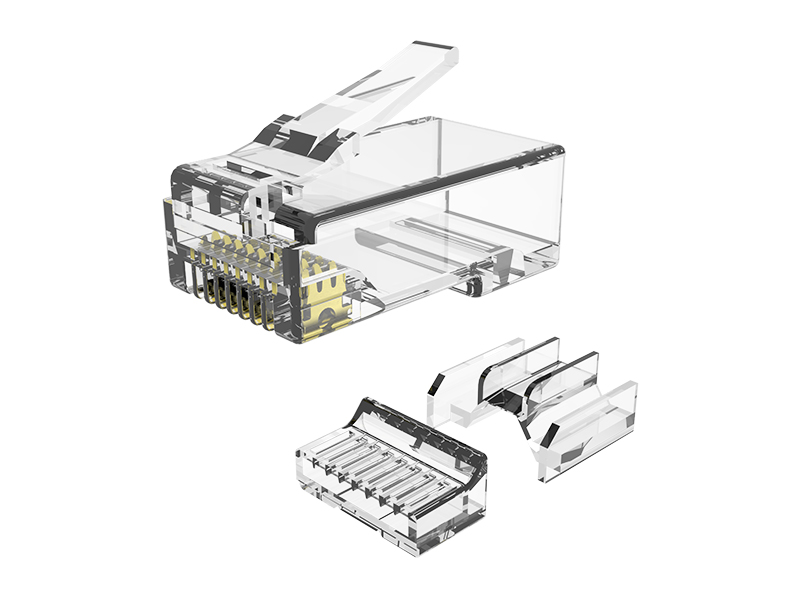

When using a toolless plug, it is necessary to consider the crimping range, as the crimping range determines the compatible wire specifications. Although the toolless plug does not require traditional crimping tools to complete the connection, it still clamps and conducts the wires internally through snap springs, spring plates, or elastic structures, which is actually equivalent to "tool free crimping". Each type of toolless plug is designed with a specified range of wire cross-sectional area, typically expressed in square millimeters (mm ²) or AWG (American Wire Gauge). If the specifications of the wire exceed the crimping range of the plug during use, it may cause poor contact, high resistance, or even overheating and burning; If the wire is too thin, it may not be securely fixed and there is a risk of detachment or leakage.

When selecting a toolless plug, it is necessary to confirm whether the crimping range of the plug matches according to the size of the cable used, especially in industrial electricity or high reliability requirements, which require strict control. Reasonably matching the crimping range can not only ensure stable electrical performance, but also improve the service life and safety of the entire system.

中文简体

中文简体 English

English Français

Français Deutsch

Deutsch عربى

عربى